About this article

Ready for a deeper dive in aqueous linings/water-based coatings. There are many environmental reasons to consider products lined with this new coating, but we want to dispel the myth these products are plastic-free (also to ensure proper end of life)

What is an aqueous lining and why is it a useful material for food packaging?

Jump to Factsheet: Aqueous lining to get acquainted with all basics facts before reading more.

What’s the difference between a lining and a coating?

Some refer to aqueous lining as ‘aqueous coating’ or ‘water-based coating’ because it is not a conventional lining. The difference is how it’s applied to the paper product. Conventional linings like PLA or PE are ‘glued’ to the paper or sprayed onto the paper, leaving a coating on the paper’s outermost layer.

Instead, aqueous lining behaves more like a coating, paint, or pigment in that it is painted onto the food packaging material. Most of that fluid soaks into the paper fibres (rather than forming an outer layer), thus constituting a structural component of the coating.

Does aqueous lining / water-based coating contain plastic?

In short, yes. Aqueous lining is a water-based dispersion system of polymers and additives to create a food-safe, grease-resistant barrier. Although aqueous lining contains a relatively small number of polymers compared to its more conventional alternatives, PE (Polyethylene) and PLA (Polylactic Acid), it cannot be considered completely plastic-free.

Then why is aqueous lining better than conventional linings?

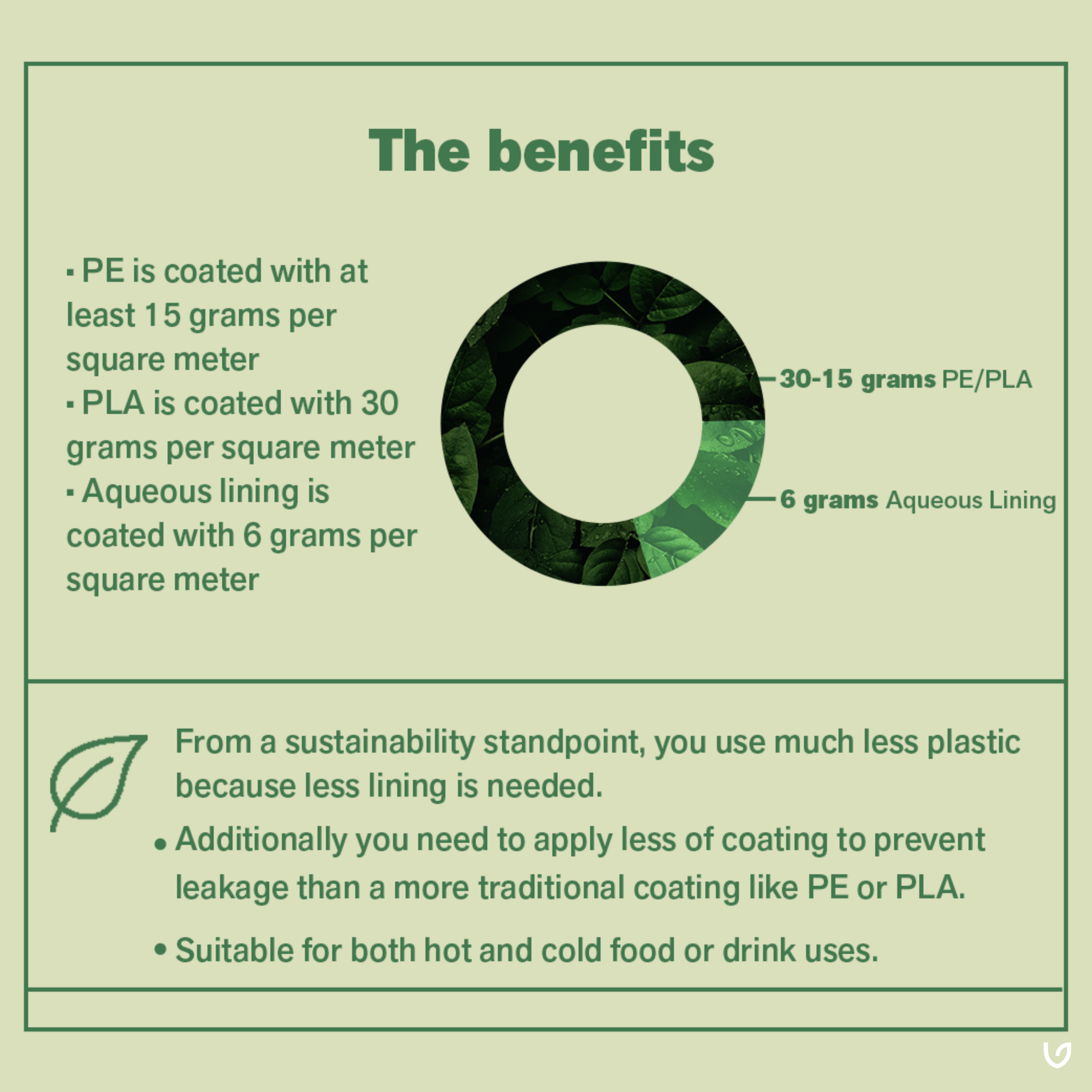

Aqueous lining is preferable because you need to apply less of it to prevent leakage than more traditional coatings, like PE or PLA. To make packaging materials suitable for food contact, manufacturers use between 15 and 30 grams of PE and PLA per square metre.

In contrast, an aqueous lining only uses 6 grams. From a sustainability standpoint, aqueous lining uses much less plastic because: a) as a material it contains less plastic and b) much less coating is needed to treat recyclable materials, like paper and cardboard.

Is aqueous lining banned in the Single-Use Plastic Directive?

According to the Single-Use Plastic Directive (SUPD), aqueous lining is not plastic-free. As it contains a small number of polymers, and therefore it must be properly labelled for sale and use in the EU to encourage responsible disposal.

Under the Single-use Plastics Directive, drink cups that contain any amount of plastic must feature the ‘Plastic in Product’ turtle logo. As for other aqueous-lined products, like food containers, these can, for the time being, continue to be used but should always be disposed of properly.

Do note that starting in 2023, the Directive will no longer consider these other aqueous-lined products plastic-free. Come 2023, using containers containing plastic for on-site consumption, including those with aqueous lining, will be banned and food service businesses must offer reusable alternatives or use unlined products in Germany. The measures may differ from one country to another.

Why are some people calling aqueous lined products plastic-free?

People call aqueous-lined products ‘plastic-free’ because of how the water-based coating is applied. Aqueous lining is not ‘glued’ to the paper or cardboard like a regular coating. Instead, it is applied like paint or ink. The SUPD defines plastic as a material which contains polymers, which aqueous lining certainly does (albeit in relatively low quantities).

The SUPD, however, does stipulate an exception for polymers used as part of glue, adhesives, and inks or paint. Of course, many manufacturers have interpreted this quite generously, advertising their aqueous-lined products as though they were actually completely plastic-free. At Verive we don’t do that. Given our commitment to transparency and anti-greenwashing, we will never use the term ‘plastic-free’ when it comes to aqueous linings.

Then why can manufacturers obtain a ‘plastic-free’ certificate?

The SUPD states that when something is a structural component of the final product, it will count as such. Because water-based coating/aqueous lining is designed to soak into the paper or cardboard, although applied like ink or paint, it certainly is a structural component of the container. Otherwise, the coating wouldn’t function and the food or drink would leak through.

The way the certificates currently work is outdated and does not account for this new material’s structural component. The certificate permits an x-percentage of polymers to allow for glue, ink, paint, etc. At present, the certification simply asks, is there less than x-percentage of polymers? Yes? Then chances are this percentage is paint, ink, or glue, the rest is polymer-free, so we can certify it as plastic-free. That’s how manufacturers manage to satisfy existing certificates. Now that you know this loophole, we encourage buyers and consumers to be wary of such ‘plastic-free’ claims or at least investigate them further.

Why is it so hard to find coffee cups fully free from plastic polymers?

Plastic is ubiquitous in food packaging because it offers the grease, fat, and liquid barrier necessary for the proper storage and transport of food. However, unlined packaging products, like burger boxes and meal boxes, are available on the market. At this point, they aren’t that great for greasy or “wet” foods as the oil will seep through unless an extra paper insert is used. Further complicating this issue is that once unlined, plastic-free food packaging is contaminated by food, it significantly reduces the chances of recyclability.

What is the best end-of-life for aqueous lining? What are the recycling and composting options?

Recycling is possible in most instances, but you need to discuss this first with your local recycling facilities and waste contractor to ensure they can correctly handle these materials. Issues to ask about include whether aqueous lining can be collected with the standard paper stream, how it will be handled from there, and if packaging heavily contaminated with food can still be recycled.

That said, because we are discussing a material that lines other materials, and is absorbed by them, it can make recycling more challenging depending upon how local recycling facilities are arranged. For instance, in The Netherlands, the way paper is recycled means it cannot currently handle the aqueous lining residue left in the fibres.

When it comes to the other two liners (PLA and PE) and recycling, these can sometimes be easier with current facilities and methods, given they can be easily soaked off (versus being embedded in the fibres). However, and we cannot stress this enough, this will vary, depending upon the national and local recycling facilities and methods.

Our paperboard takeaway meal boxes and cups made from bamboo paper both utilise an aqueous lining and are fully compostable according to the EN13432 certification.

Have more questions about water-based coatings?

And feel free to get in touch! We’re always happy to respond to any questions you might have about our products, materials, and the latest trends in alternative food packaging. You can find us here info@verive.eu